Polyethylene Sheeting and Film

What is polyethylene sheeting?

Polyethylene sheeting is made from a polymer prized across many industries for its durability, flexibility and moisture resistance. The properties of this versatile plastic make it ideal for applications in:

- Construction (humidity control and water damage prevention)

- Packaging (seal and protect products like food and medical items)

- Manufacturing (protect equipment)

- Automotive (prohibit rust)

Poly sheeting is available in different thicknesses, grades, and colors. Depending on the application, additives can be applied to accentuate certain characteristics.

Custom poly sheeting manufacturing

All of our poly sheeting and film products at Versa Pak are custom-manufactured to meet the production capabilities, properties and top quality you need in plastic packaging.

Versa Pak’s state-of-the-art co-extrusion line and in-house research and quality lab allow us to customize multi-resin formulas to meet your needs both today and into the future.

Polyethylene Sheeting and Film Features

- Thickness from .0005 to .010 mil.

- 5-inch to 122-inch sheeting

- Wide spectrum of colors and prints

- Available in the latest co-extruded (Co-Ex) blend of two or more resins engineered into a multi-layer film

- See more capabilities here.

As an SQF-certified manufacturer, all of our resin is top-quality virgin and FDA-approved polyethylene provided by a stable supplier.

Custom Polyethylene Sheeting

Center-Fold Poly Sheeting

(CF Sheeting)

A double layer of sheeting, cut on one side and folded on the other; provides ease of use when wide sheeting is needed.

Single Wound Poly Sheeting

A single layer of sheeting, cut on both sides; most often used with machine feeding.

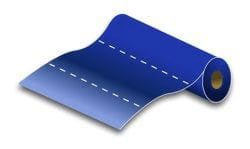

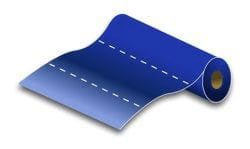

Serrated Poly Sheets

Sheets with serrated tear lines speed production, precision and quality control. Customized to your product features.

Shrink Sheeting

Shrink bundling sheeting for heavy-duty packaging and product protection.

Center-Slit Gusseted Sheeting

Plastic sheeting with an expandable, gusseted side and conveniently placed on a roll for ease of use.

Additional Resources on Polyethylene Sheeting and Film

What are polyethylene bags and sheeting used for?

Custom Polyethylene Film

Poly Film with Continuous Vertical Perforations

A continuous roll of plastic film or bags, perforated at specific lengths for easy tear-off.

Single Wound Poly Film

A single layer of film, cut on both sides; most often used with machine feeding.

Shrink Bundling Film

Shrink film for heavy-duty packaging and product protection.

Center Slit Gusseted Film

Plastic film with an expandable, gusseted side and conveniently placed on a roll for ease of use.

Dual-Colored Film

Dual-colored film for enhanced light-blocking and aesthetic solutions. Options include black/white and white/gray.

Stretch Hooder Film

Stretch hood film is created from a tubular extrusion. One end is sealed, and the other can be stretched over a palletized load.

Frequently Asked Questions about Polyethylene Film and Sheeting

Polyethylene sheeting is available in a range of thicknesses to suit different application needs, from .0005 to .010 mil.

Yes, polyethylene sheeting is commonly used for outdoor applications due to its excellent resistance to moisture, UV rays, and environmental factors. We can create a product incorporating Ultraviolet Inhibitor (UV) technology and more, depending on your needs.

Our polyethylene sheeting is sold in rolls. Let us know about your needs and we can create a custom quote for you.

Versa Pak offers poly film in thicknesses from .0005 to .010 mil, and widths from 5-inch to 122-inch.

The lead time for custom plastic products from Versa Pak can vary depending on factors such as order complexity, quantity, and current production capacity. However, we’re committed to providing efficient turnaround times. Your Versa Pak sales rep will help you get a better estimate of the lead time for your custom plastic products.

Yes! We can create custom blends and include properties such as ultraviolet inhibitor (UV) EVA, anti-static, hi-slip, low-slip and more.

Yes. All of the poly products that we manufacture are FDA-approved, SQF-compliant, and Kosher compliant.

LLDPE (Liner Low Density Polyethylene) and LDPE (Low Density Polyethylene) differ in their molecular structure. LLDPE has short, random chain branching, offering superior tensile, impact, tear strength, and seal strength compared to LDPE, which has highly branched, long chains providing acceptable toughness, flexibility, optics, and permeability but is not as strong as LLDPE. While not as strong as LLDPE resins, LDPE provides excellent shrink properties.

Versa Pak Poly Sheeting and Film Manufacturing Capabilities

- FDA-approved

- SQF-certified

- IMS-certified

- CO-EX blends

- Custom Engineered Films

- Converter Film

- Ultraviolet Inhibitor (UV)

- EVA

- Anti-static

- Hi-Slip

- Low-Slip

- LDPE & LLDPE

- Slit seal

- Coreless winder

- Flame retardant

- Volatile corrosion inhibitor (VCI)

- Electro Static Discharge and Static Dissipation

- Recycled materials

- Various separation and venting possibilities

- Multiple colors, clears and print options

- And more